COMPONENTS

Piston

- Monoblock Piston in Alloy Nodular or Grey Cast Iron

- High Strength Cast Aluminum Alloy Piston with Ring Carrier

- Combined Piston with Forged Alloy Steel Crown and Forged Aluminium Alloy Skirt

- Combined Piston with Forged Alloy Steel Crown and Nodular Cast Iron Skirt

- Ring Grooves Induction hardened/Chrome Plated and Ground

- Crown Nitrided and Skirt Graphite Coated or Phosphoted

- BV, GL Certificate

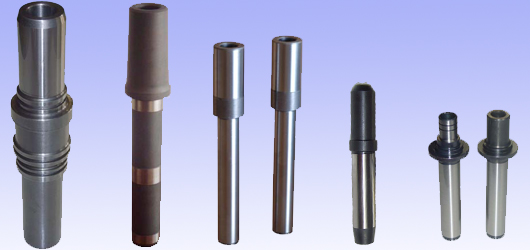

Valve Spindle

- Valve materials are compliant with European standard BS EN 10090:1998

- Martensitic Steel: X45CrSi9-3(1.4718 or EN52), X40CrSiMo10-2(1.4731)

- Austenitic Steel: X33CrNiMnN23-8(23-8N or 1.4866),X53CrMnNiN21-9(1.4871), X50CrMnNiNbN21-9(1.4882) )

- Super Alloy: NiCr20TiAl(Nimonic80A or 2.4952), Inconel751

- Stellite#6, Stellite#12, Deloro 50 for welded seat via PTA process

- Upset forging and die pressing for forged blanks

- Controled heat treatment for achieving proper mechanical properties and metallurgical structure

- Stress released completely for microstructure and dimensional stability

- Stem hardened via Tufftriding/ionitriding or chrome plated

- Supersonic detection for welded seat and friction welded stem

- Entire valve dye penetrant or magnetic powder inspected correspectively for different valve materials

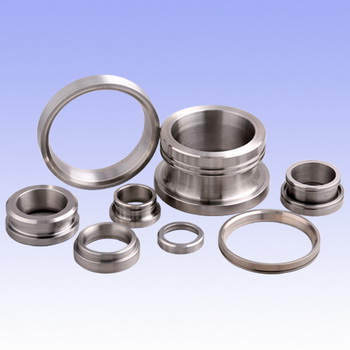

Seat Ring Insert

- Made in X45CrSi9-3(1.4718), X40CrSiMo10-2(1.4731) which are complaint with European standard BS EN10090

- Seat Stellite welded or induction hardened

- Provide cooled seat rings in super alloy 60Cr-40Ni(K6040)

- Stress released completely for dimensional stability

- Seat face concentric to O/D within 0.0008’TIR

- O/D roundness within 0.0004’

Cylinder Liner

- Cr-Ni-Mo alloyed cast iron with over 90% pearlite achieving excellent abrasive and heat resistance in HFO condition

- Bore plateau honed with cross hatch pattern at a specified angle

- Surface Tufftrided or phosphated as per special needs

- O/Ds concentric to bore within 0.002’ TIR

- Pressure tested for free of leakage

Cylinder Head

- Nodular Cast Iron GGG60

- Seat rings and valve guides installed

- Pressure tested for free of leakage

- CCS Certificate

Guide

- Material in GG25, high-phosphorous iron or bronze

- Plateau honed bore for better running-in

- Surface Tufftrided or phosphated as per special needs

- O/D ground and concentric to bore within only 0.0008’

RANGE

| Product | Model |

|---|---|

| MAN/B&W | 16/18, 16/24, 17.5/22,20/27, 21/31, 23/30, 23.5/33, 25/30, 27/38, 28/32, 32/40, 40/45, 40/54, 48/60, 52/55, L/S26, L/S35, L/S42, K42EF, K45GF, T23 |

| PIELSTICK | PA4, PA6, PC2, PC2.2, PC2.5, PC2.6 |

| SULZER | AL20/24, AL25/30, ZL40/48, ZAV40S, RTA38, RTA48, BAH22 |

| DEUTZ | RBVM350, BA6M528, RBVM540, BAM628, RBVM640, BF 6M716 |

| MAK | M281, M331, M423, M452, M453, M551, M552, M601 |

| WARTSILAR | WARTSILAR |

| MTU | 1163, 956 TB82/TB92 |

| MWM | 620/604B |

| DIAHATSU | DS-18, DS-19, DS-22, DS-26, DS-28, DS-32, PS-18, PS-20, PS-22, PS-26D, PS-26H, PKTB-14, PKTB-16, DL-16, DL-19, DL-20, DL-22, DL-26, DL-28, DL-32, DL-40, DK-20, DK-28 |

| YANMAR | RAL,MAL,GL,KFL,HAL-TN,ZL-ST,UAL,S165,S185,M200,M220,N260, N330 |

| AKSAKA | DM51, DM46, DM38, DM36, DM33, DM28, A41, A37, A34, A31, A28, DH46, AH27, AH40F, K28, 6U26(L), 45/80D, 45/75 |

| UET/UEC | 65/135D, 50LSII, 45/115H, 37/88H, 37LA, 52/90C, 52/90D, 52/105D, 52/105E, 52/125H, 45/80D, 45/75C |

| HANSHIN | 6EL-44,6EL-40,6EL-38,6EL-35,6EL-32,6EL-30,6ELS44,6ELS35,6ELS32,6LU50A,6LU46A, 6LU38,6LU35,6LU32,6LUS40,6LUS38,6LUS35,6LUD32,6LUD26,LH32,LH31,LH28,6ILIS28,Z6320ZSS |

| NIIGATA | L13, 6L13AHS, 6L/6HS, 6L16X, 6L20X, 6L22X, L25BX, PA5, MG25BX, MG28BX, M28AFTE, M28KEHS, 6M31AFTE, 6MG31BX/EZ, M34GX, M37BHS, 6M42 |

| SKL | NVD26, NVD36, NVD48, VD26/20,VD36/24, VD48/42 |

| RUSTON | AP230, RK215, RK270,RK 280 |

| Mirrlees | 'E 'Range, K-Major |

| ALCO | EMD567, EMD645, EMD710, GE 7FDL, ALLEN, PAXMAN, GMT, FUJI, MAKTA |